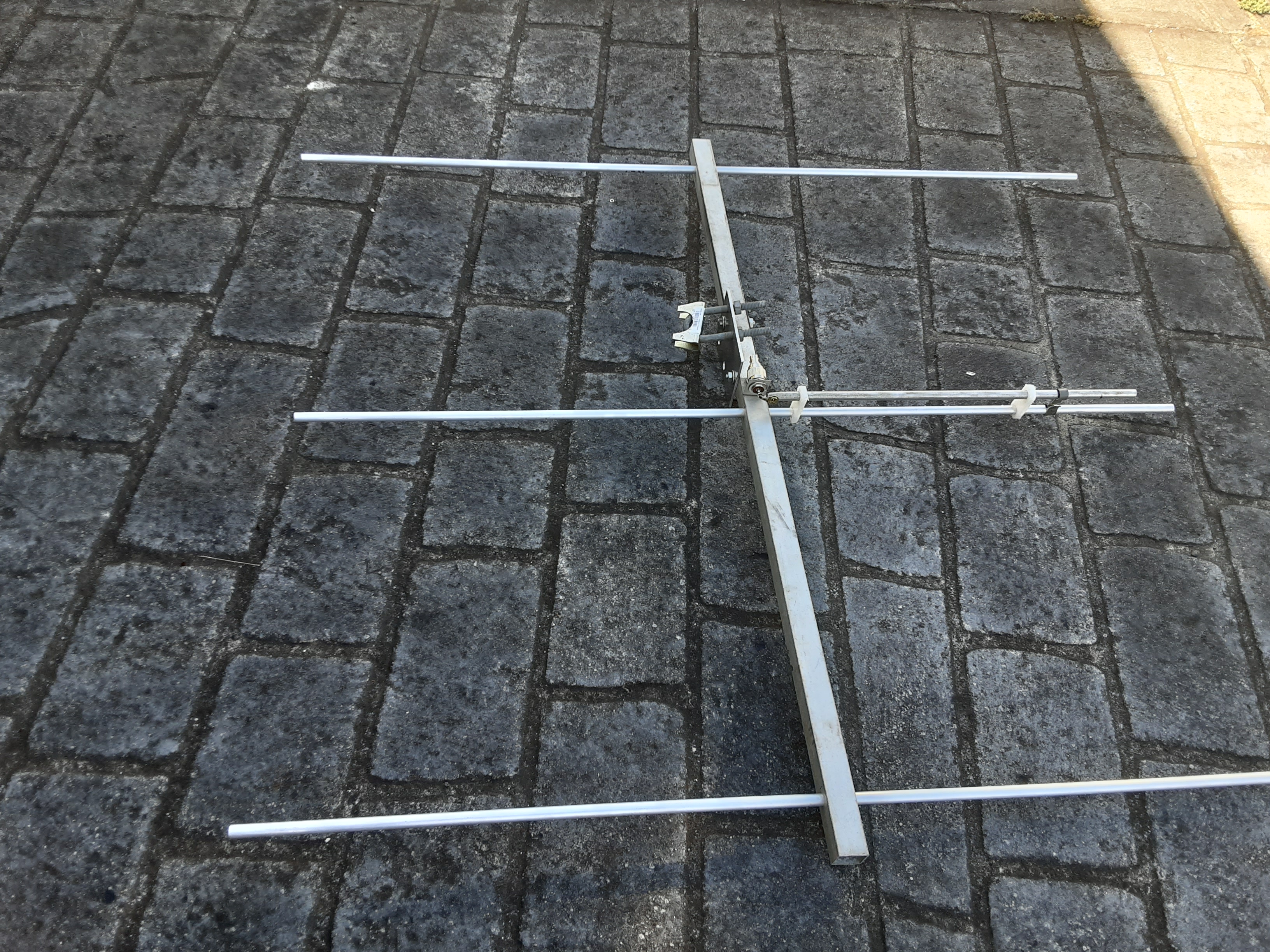

This antenna is cut for 145.00mhz

After moving house and a 10 year absence from 6M, 2M & 70CM SSB, I

finally restored my old 2M and 70CM antennas, and now having 2 radios

for 2m SSB with one normally runing WSPR mode 24/7 on 2m and additional

antenna was needed for monitoring and swap-around when needed.

There are some advantages in having a lower gain beam for WSPR when there is a lot of stations spread around the compass.

Using

readily available material from the local hardware shop a 3 element

beam was constructed.

The

design is NBS (National Bureau of Standards) which were developed

around the late 70’s for various sized optimised yagis with

computation charts for various diameter and elements Vs various

length booms.

This

design consists of 3 elements with nominal 7.2dBd gain with elements

of 10mm dia. and a 25mm square aluminium

boom.

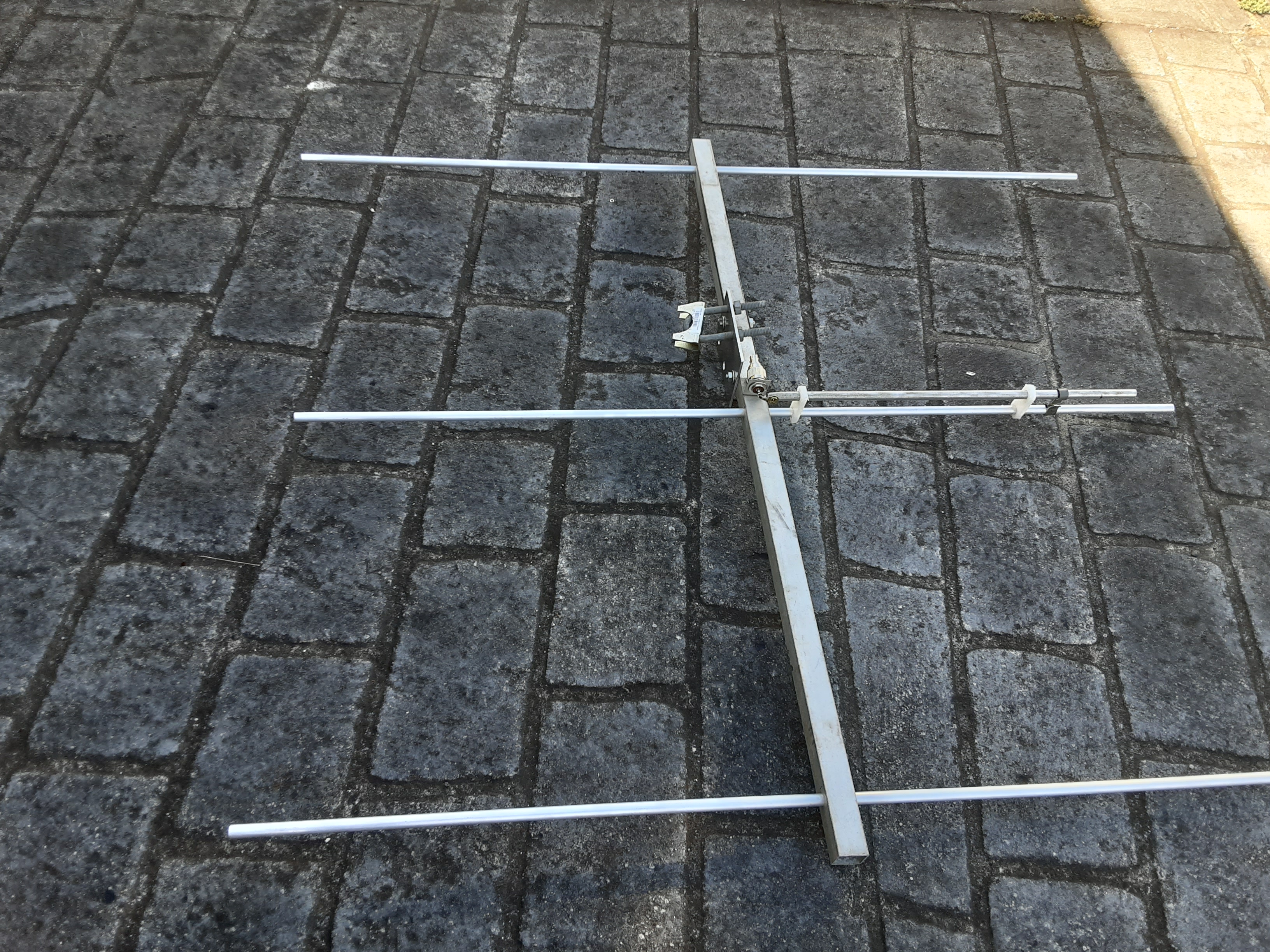

The

match device is a cross between Gamma match and a half folded dipole, after using on my previous 6m

build and chosen because if its simplicity and DC grounding of the coax. A

gamma match uses a capacitor to cancel out the inductance of the

gamma rod, whereas in this system the capacitor is gone and driven

element length and

matching point is altered to give the impedance

match and cancellation of reactance.

Requirements:

Pedestal

drill

Battery

drill

1/8” & 10mm drill bits

1/8th

Aluminium rivets and rivet gun

Self

tapping screws 12mm long

1 x

3m length 25 x 25 x 1mm square aluminium,

2 x

3m length x 10mm dia round aluminium tube

100mm

of aluminium strip 12mm wide x 1mm thick to make the gamma

rod/element connecting strap.

Some

25mm wide x 5mm thick x 50mm long strips of plastic to make supports

for gamma rod. You might find a plastic chopping board in the kitchen

to cut a bit off while the boss is not looking. This material is not

real critical as to what you use as long as it is stable in the heat

and weather.

Construction:

Boom

(25mm Square) – Using a bench/pedestal drill and a 10mm twist bit

make 3 holes centrally at the relevant positions for each of the

elements and

cut off the excess length.

Elements - Cut to length as required.

The

short length will be for the director and the long one will be for

the reflector.

Mount

the element centre sections centrally in their correct locations in

the boom using the self tapping screws to hold them secure. Do not

drill/screw into the elements as this weakens them, just let the

screws push tight against them. Put a bead of Silastic around the

tubes where they fit through the boom. This is to prevent wind

vibration eventually wearing through the elements.

Matching rod:

The

2 insulating supports consist of two 10mm holes 30mm apart in a

50mm long 6mm thick piece of plastic and need to be installed on one

side of the driven element section.

The

matching rod has a 10mm long section at the

end where 12mm of the tube is removed, i.e, half round.. This allows the

coax centre attachment screw a bit of space to protrude.

Matching

arrangement - this picture for illistration only:

Bevel

both sharp ends of the tube to allow easy fitting through the plastic

supports.

Mount

all as show in diagram.

The

connecting strap is 12mm wide aluminium 1mm thick. Form it around the

tubes as shown so that 10 mm dia holes at 30mm centres match the

insulating supports.

Feed point:

I

used a SO239

connector fitted through a bit of galvo plate similar as shown except where coax comes thru there is an SO239 socket with very short wire to screw.

I should have

used an "N" connector socket rather than a SO239 as they have better weather proofing qualities.

The galvanised plate bent at right angle as shown, which is secured to the boom

using self drilling screws.

Feed

point -:

All

this is then thickly coated in epoxy resin (5 minute araldite or

similar) to seal the coax and connections from moisture. Cover all

this with tape or plastic to prevent sunlight UV degradation of resin

over time.

Tuning:

Is

done using your favourite method. Adjusting the element length moves

the frequency of lowest point of SWR but should not be required, and the strap position adjusts

for

lowest SWR at that frequency.

These adjustments do interact slightly.

I tuned mine on a short pole at about 2m off the ground so that

adjustments were easy

to reach.

Just make sure that you are reasonably clear of large metal objects

i.e. cars and sheds, and pointed away from same.

Once

satisfied do a check in the final installation location. Seal ends of elements (silastic) as a measure to

prevent water corrosion.

I

tuned mine to lowest SWR at 145 so that it is usable from 144

to 148

VK7DC

HOME

|